Control system FOOD.CON 2

First of a new generation

Creating high-quality products in the food industry means balancing the desire for flexibility in the production of goods with absolute process reliability. This requires constant, seamless monitoring of all processes, as well as careful documentation of every intervention in the program flow.

High flexibility through simple operation

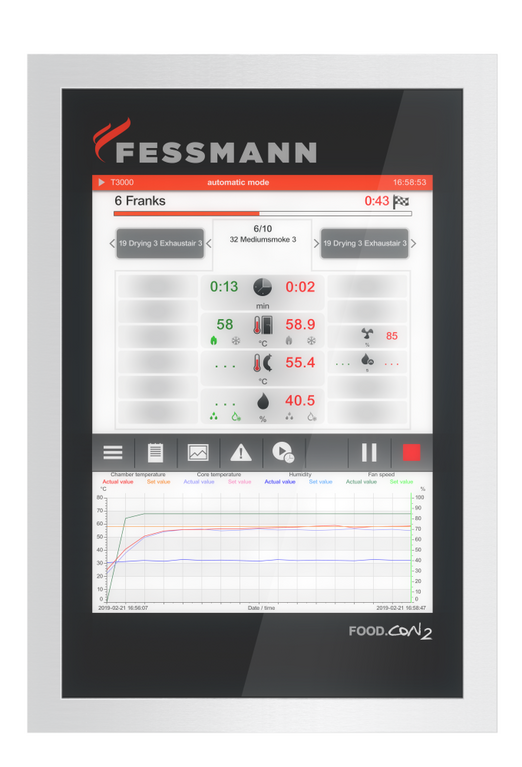

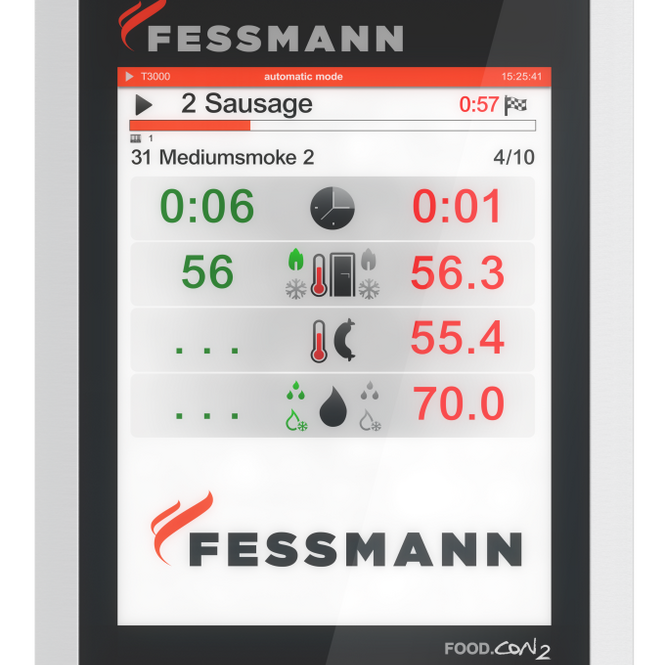

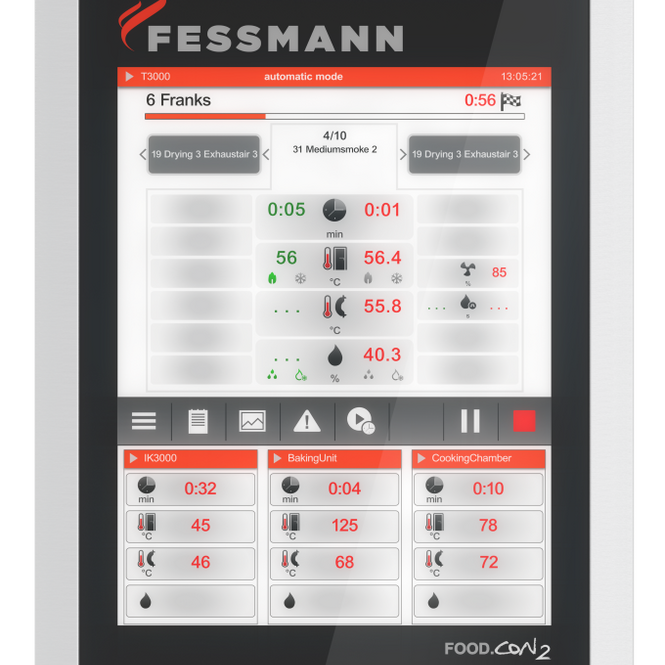

The FOOD.CON 2 adapts to your requirements. Equipped with a 12" touch screen made of special protective glass, the control is intuitive to operate and the self-diagnosis function through fieldbus communication with all important components of the system ensures minimum downtimes and maximum system availability. Program optimizations can be carried out via remote maintenance via external access or directly via smartphone.

Maximum safety at all times

During operation, the FOOD.CON 2 enables the precise monitoring of all important parameters in the system: chamber temperature, humidity, core temperatures and much more are permanently recorded and made available as graphic evaluation for quality control. Up to 300 programs can be stored for automatic operation and protected by passwords at various user levels.

The connection to the FOOD.LOG software enables additional, even more comprehensive possibilities for process monitoring.